The Impact of 3D Printing on Consumer Electronics

22 January 2026

3D printing is no longer just a futuristic concept—it’s transforming industries today, including consumer electronics. This cutting-edge tech is shaking things up, allowing manufacturers and even everyday users to create intricate components, customize gadgets, and reduce production costs. But how exactly is 3D printing changing the landscape of consumer electronics? Let's dive in!

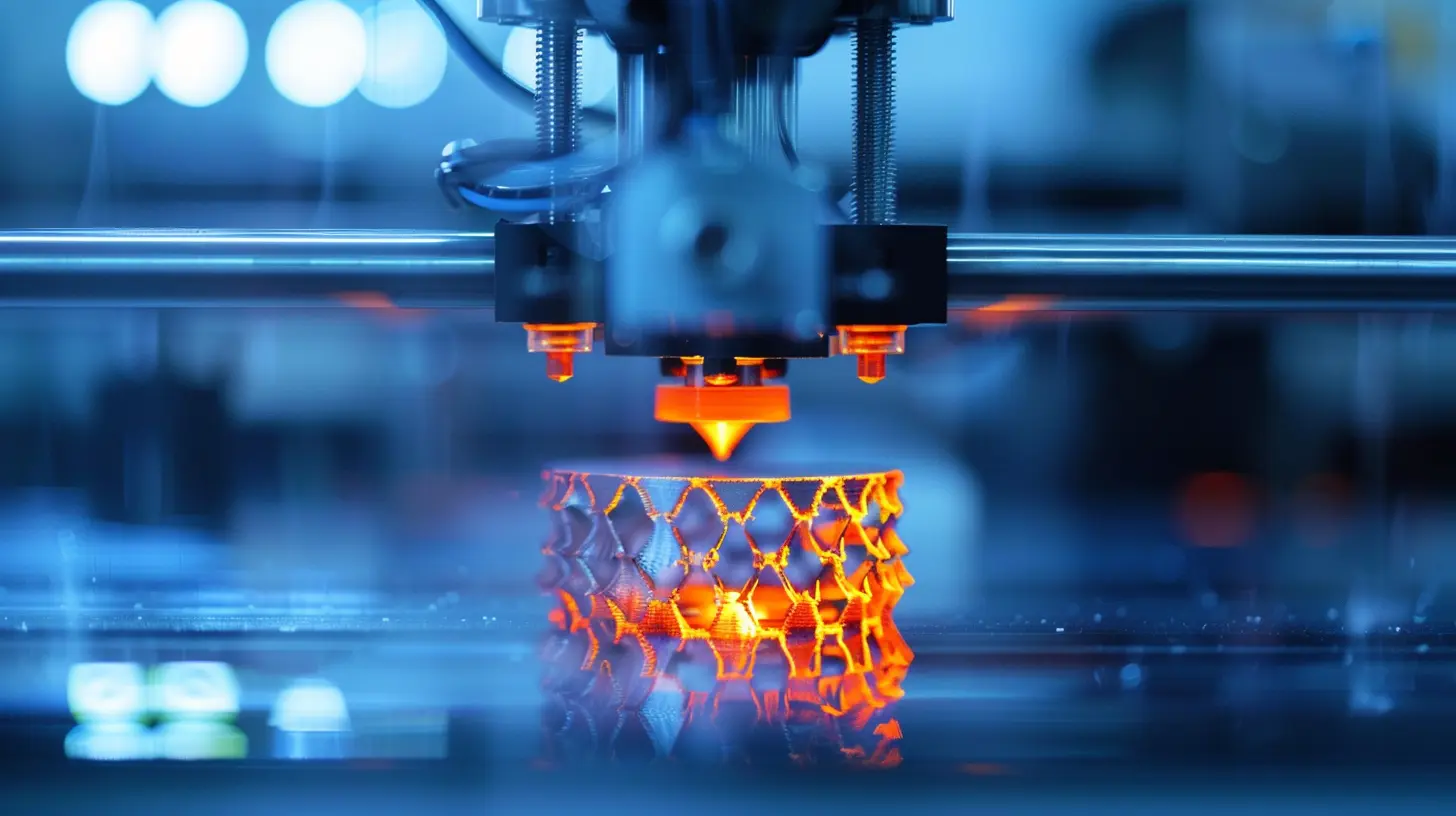

What Is 3D Printing?

Before we get into its impact, let’s get a quick grasp of what 3D printing actually is. Often referred to as additive manufacturing, 3D printing builds objects layer by layer using a digital blueprint. Unlike traditional manufacturing, which involves cutting and molding materials, this approach adds material progressively, making it more efficient and waste-free.From aerospace to medicine, 3D printing is making waves in multiple industries—but when it comes to consumer electronics, its effects are particularly groundbreaking.

How 3D Printing is Revolutionizing Consumer Electronics

Think about the everyday gadgets we rely on—smartphones, headphones, smartwatches, gaming consoles. 3D printing is rewriting how these products are designed, produced, and customized. Here’s how:1. Faster Prototyping and Product Development

Product development used to take months, sometimes even years. Engineers would go through countless revisions, waiting for manufacturers to refine and produce prototypes.Now? 3D printing slashes that timeline. Companies can instantly print prototypes, test their functionality, and make adjustments—all in-house. This means faster innovation and quicker time-to-market for new electronics.

Take smartphone makers, for example. Rather than waiting for external suppliers, they can 3D print phone casings, internal components, and accessories almost instantly. This agility is a game-changer in an industry where speed is everything.

2. Customization Like Never Before

Let’s face it—most consumer electronics look pretty similar. But not for long!3D printing allows users to personalize their devices however they like. Want a phone case with your name engraved? Done. Need custom-fit earbuds designed for your unique ear shape? Easy.

Even companies are taking advantage of this. Brands are now offering personalized gadgets where users can tweak colors, textures, and even the shape of their products. This level of customization wasn’t realistic before, but 3D printing is making it the new norm.

3. Lower Production Costs and Less Waste

Traditional manufacturing methods involve high setup costs—think molds, assembly lines, and extensive labor. Plus, a significant amount of material gets wasted in the process.With 3D printing, manufacturers can create electronics using exactly the right amount of material, cutting down on waste. Also, because complex parts can be printed as a single piece, companies save on assembly costs.

This is especially beneficial for startups and small businesses that want to enter the consumer electronics space. With lower costs, they can bring innovative products to market without competing with billion-dollar giants.

4. Repair and Replacement Made Easy

Ever had a device break down because of a single tiny component? Normally, you’d have to wait weeks for the replacement part—or worse, buy an entirely new device.3D printing changes that by giving users the power to print their own spare parts. Imagine having a 3D printer at home that can create replacement buttons, battery covers, or hinges in minutes!

Companies like HP and Dell are already using 3D printing to manufacture spare parts on demand, reducing inventory costs and ensuring customers get replacements faster.

5. Enabling Complex, Lightweight Designs

Ever noticed how electronics are getting slimmer and lighter? That’s partly thanks to 3D printing.Traditional manufacturing has limitations—certain complex structures just aren’t feasible. But with additive manufacturing, designers can create intricate, lightweight designs that wouldn’t be possible otherwise.

This is especially useful in wearables—think smartwatches or AR glasses. With 3D printing, companies can sculpt products that are ultra-light yet incredibly durable, making them way more comfortable for everyday use.

Challenges of 3D Printing in Consumer Electronics

Of course, no technology is without its hurdles. While 3D printing is revolutionizing electronics, there are a few challenges to address:1. Material Limitations

Most consumer electronics rely on specific materials like metals, silicon, and high-grade plastics. Right now, 3D printing materials are limited, and not all of them match the durability and conductivity standards required for electronics.However, research is pushing the boundaries, and we’re seeing newer conductive filaments and advanced resins that could soon bridge the gap.

2. Quality Control Issues

Mass-produced electronics undergo rigorous quality checks, ensuring every single unit is identical. With 3D printing, the consistency isn’t always perfect—small defects can creep in due to layering inaccuracies or material flaws.For now, 3D printing is great for prototyping and customization, but achieving mass-scale uniformity is still a work in progress.

3. Production Speed Constraints

While 3D printing is fast for prototyping, it’s not the best for high-volume production—at least, not yet. Traditional manufacturing still wins when it comes to speed and efficiency in mass production.That said, as 3D printing technology improves, we could see it catching up sooner than we think.

The Future of 3D Printing in Consumer Electronics

So, where is this all headed?3D printing is still evolving, but its impact on consumer electronics is only going to grow. In the coming years, we can expect:

- More Advanced Materials – As new materials emerge (like flexible, conductive inks), we could see more fully 3D-printed electronics.

- On-Demand Manufacturing – Instead of mass-producing gadgets, companies might print them on demand, reducing waste and inventory costs.

- Home 3D Printing for Consumers – Imagine downloading a blueprint and printing your own phone case, smartwatch band, or even circuit board at home!

- Greater Sustainability – 3D printing could help reduce electronic waste by allowing users to repair instead of replace their gadgets.

With these advancements, the consumer electronics industry is set for a massive shift—one that puts more power in the hands of both manufacturers and consumers alike.

Final Thoughts

3D printing is no longer just a cool experiment—it’s shaping the future of consumer electronics. From faster prototyping and customized designs to reduced production costs and easier repairs, the benefits are undeniable.Sure, there are some challenges to iron out, but with rapid advancements in materials and technology, 3D printing is well on its way to becoming an integral part of the electronics industry.

If you’re a tech enthusiast, now’s the time to keep an eye on this space—because what’s coming next might just redefine the way we interact with our gadgets!

all images in this post were generated using AI tools

Category:

Tech InnovationsAuthor:

Adeline Taylor

Discussion

rate this article

2 comments

Daniel McMillan

Exciting insights on future possibilities!

February 9, 2026 at 12:07 PM

Adeline Taylor

Thank you! I'm glad you found the insights exciting!

Ava Rios

Print, don’t shop—revolutionize!

January 22, 2026 at 5:57 AM

Adeline Taylor

Thank you! Embracing 3D printing can indeed transform how we approach consumer electronics, prioritizing personalization and sustainability over traditional shopping methods.